In today’s automobile industry, precision and reliability are non-negotiable. When you are making vehicles, every part matters. Even a small casting error can cause a big problem later. That’s why choosing the right automobile parts casting partner is important.

It’s not just about pouring molten metal into a mould. It’s about getting every step right – from pattern design to final inspection.

At Sunflame Technocast, we specialize in automobile parts casting using both sand casting and shell mould casting processes. Over the years, we’ve worked with automotive OEMs, tier-1 suppliers, and aftermarket manufacturers across India and abroad. Our goal is simple: deliver cast parts that perform reliably under real-world conditions.

What Makes Sunflame Technocast a Leader in Automobile Parts Casting

Every auto manufacturer needs a casting partner who understands their pain points. Tight delivery schedules, high tolerances, material consistency, and cost control. At Sunflame Technocast, we’ve structured our processes to solve exactly those challenges.

We have over a decade of focused experience in automobile parts casting. Our facility is equipped with modern melting units, CNC pattern-making, and in-house testing capabilities. But beyond machines, it’s the team and the mindset that make a difference.

We have handled complex projects like cylinder head castings where thermal stresses and dimensional accuracy were key. In one case, a client faced repeat failures in a housing part due to shrinkage. Our engineers redesigned the gating system and used shell moulding for precision. The result? Zero rejections in the next 3,000 pieces.

This level of expertise does not come overnight. It comes from years of hands-on work, strong technical knowledge, and a deep understanding of automotive requirements..

How Sand Casting and Shell Mould Casting Deliver Flexible Solutions

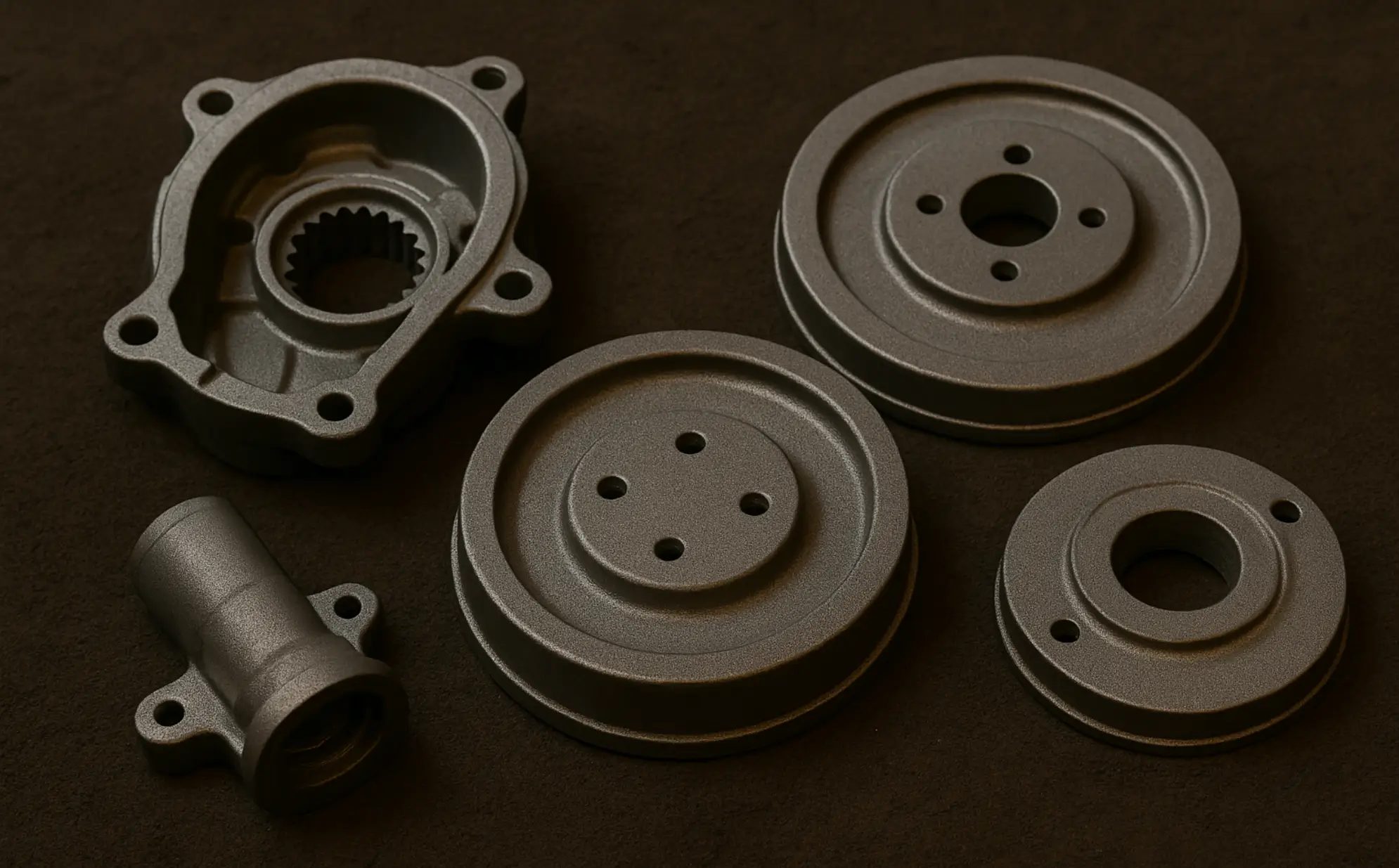

We use both sand casting and shell mould casting depending on the complexity and function of the part.

Sand casting is highly versatile and cost-effective. It’s ideal for large, complex shapes like differential housings or brake drums. We use high-quality silica sand and resin-bonded systems to ensure dimensional stability and surface finish.

Shell mould casting gives us tighter tolerances and a better surface finish. It’s suitable for intricate parts that demand higher precision, like valve covers, impellers, or pump housings.

By offering both processes under one roof, we give our clients the freedom to choose what suits their design, budget, and timeline best. This flexibility is what sets us apart in the automobile parts casting segment.

Also, discover about what is the advantage of sand casting.

Why Manufacturers Trust Sunflame Technocast for Automobile Parts Casting

1. Industry-Specific Expertise

We don’t do generic casting. We focus on automobile parts casting. That means we understand functional requirements like wall thickness, cooling behavior, and post-processing tolerances. We collaborate closely with your design or production team to avoid costly trial and error.

2. Quality Assurance at Every Step

Every part goes through strict inspection – Sand Testing and Analysis, Spectrometer Testing, Chemical Analysis, PMI Testing, Mechanical Testing, Impact Testing, Hardness Testing, etc. We follow ISO-certified procedures and maintain detailed production traceability.

Know more about the Testing Facility at Sunflame Technocast for Quality Sand Castings.

3. Strong Communication & On-Time Delivery

We know auto manufacturing runs on tight schedules. That’s why we plan ahead, share regular updates, and never overpromise. Many of our clients say our response time and delivery consistency are what made them stay.

Built for Long-Term Value and Growth

At Sunflame Technocast, we believe in investing for the future. We continuously upgrade our production lines with better energy management, sand reclamation, and simulation-based casting design. Our team gets regular training to stay aligned with industry best practices.

We also follow environmentally conscious casting practices – minimizing scrap, reducing emissions, and recycling sand. These are not buzzwords. They are part of how we deliver better parts at lower costs without compromising on safety or quality.

As electric vehicles (EVs), hybrid systems, and lightweight engine designs become more common. We are adapting our methods to serve those needs too. We see automobile parts casting not as a static process but as a growing technology space.

Talk to a Team That Understands Casting and Commitment

Choosing the right partner for automobile parts casting is about more than specs and quotes. It is about finding a team that listens, understands, and delivers on time every time.

At Sunflame Technocast, we combine proven expertise with a practical approach. No jargon. No inflated claims. Just well-made parts, tested for performance, backed by responsive support.

If you are a manufacturer looking for a dependable supplier for sand casting or shell mould casting, let’s connect. We will walk you through our process, share case studies, and explore how we can help your production run better.

Conclusion

Sunflame Technocast leads in automobile parts casting because we focus on what matters: quality, precision, consistency, and communication. With sand and shell mould casting under one roof. And a team that understands automotive challenges. We are here to make your parts perform better on the line and the road.

Contact us for more information.

📞 +91 990-461-1655 || 📞 +91 992-491-1655 || 📧 info@sunflametechnocast.com